Building Science Soup

Building science is well established in many parts of the world including Europe, Canada and the US. However building science terminology varies between all countries, even those where the specialisation is just emerging among the fields of architecture, engineering and construction.

New Zealand and Australia have individual intricacies based on standards and code wording. Terms are often a relic of the past or a result of convoluted committee processes rather than a scientific approach to delivering outcomes.

A passionate proponent of quality construction might argue that it’s the outcome we are after, so it does it really matter what things are called?

In a region where we can’t even agree if horizontal framing members are ‘nogs’ or ‘dwangs’, do we really have any hope of standardising more complex terminology?

At the dawn of this exciting new era of Southern Hemisphere building science, we have an opportunity to define our terms for a better understanding of the whole building sector.

Modern Metrics

It’s not helpful if someone says to you, “you need a membrane that has 10 grains of water vapour per hour, per square foot, per inch of mercury” and some other person says, “you need 0.57 micrograms, per second, per square meter, per pascal”.

So we (excluding the US) chose a single numbering system.

The world around us is governed by the forces of nature. Science and engineering are described by numbers and metrics and a single numbering system makes our life easier. Most of the modern world has adopted the metric system and SI units for numbers. But what about the words we use to describe these metrics?

Words Matter

Communication of the design intent is governed by the language we use, and a single nomenclature makes our life easier. If we can’t communicate it, we can’t design it, and if we can’t design it, we can’t build it. So what should we call things?

New Zealand and Australia seem to be borrowing terminology from other parts of the world to explain new products and new construction approaches to deliver building science-based construction systems. Some of this terminology will suit us well, but let’s take a look to ensure we know what we’re talking about and agree on terms that are fit for purpose.

Moisture Management

In essence, building science is about managing moisture in construction systems.

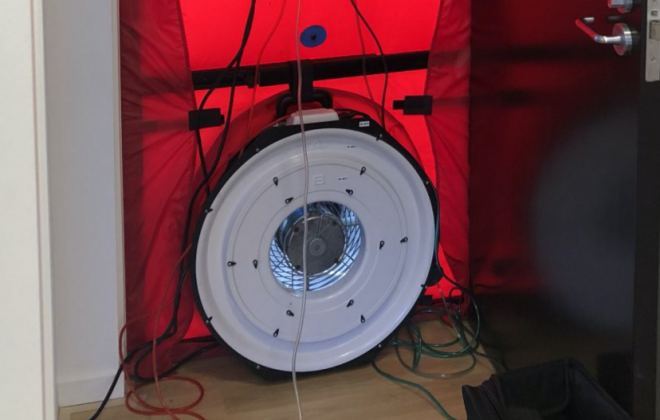

As buildings become more airtight for energy efficiency reasons, the risk of trapping internal moisture becomes considerably greater. Why then do we want airtight buildings if they create problems?

Well, it so happens that airtightness is the solution to another fundamental problem – water leaky building envelopes. The more airtight the waterproofing layers, the more watertight they are. It also happens that if you engineer construction systems based on science and maths you will not trap moisture.

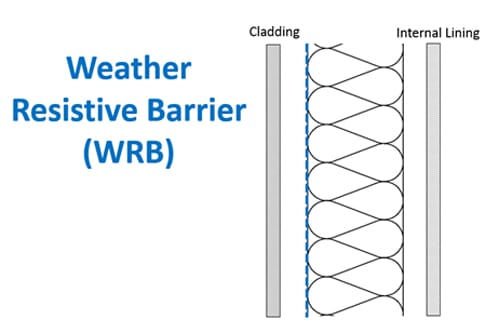

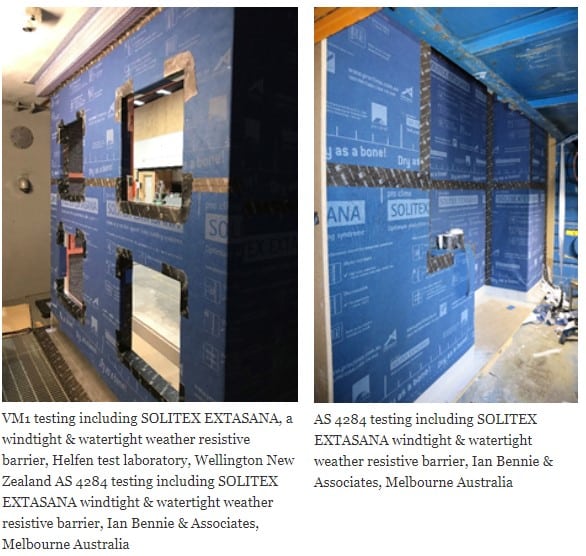

Weather Resistive Barrier

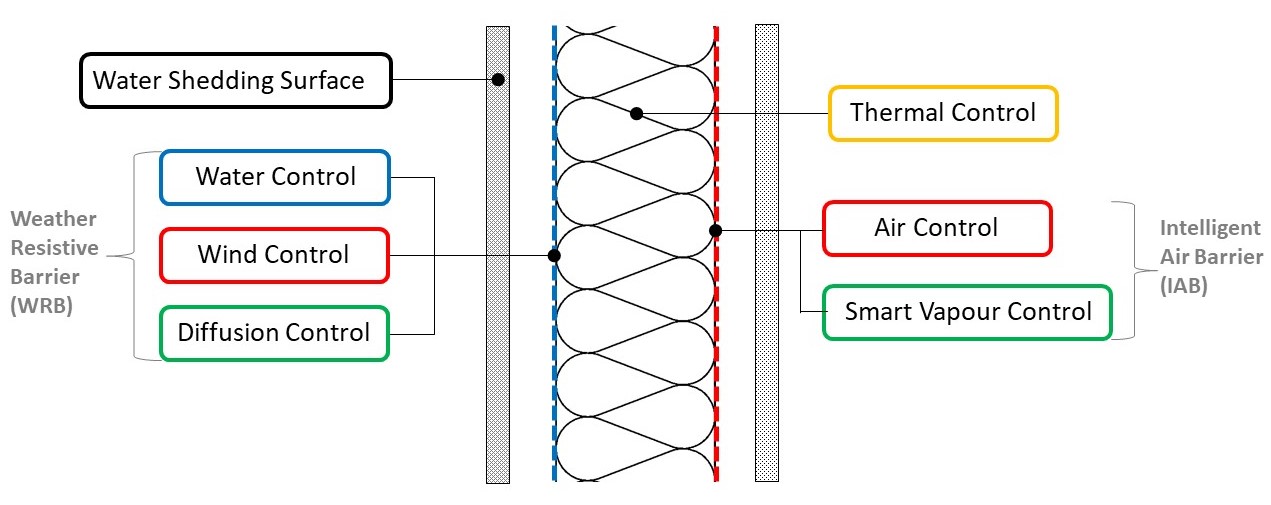

This leads to a Weather Resistive Barrier (WRB); a term commonly used in the US.

Weather could be defined as a combination of wind pressure and rain or driving rain. The WRB acts as a drainage plane for any water that may get past the cladding. (And it’s not a question of ‘if’ water gets past the cladding, but rather a question of ‘when’. No cladding is perfect.)

The word ‘resistive’ is important as real barriers do not exist in real buildings. ‘Resistive’ implies the objective is to get as close as possible to a perfect wind tight and watertight seal to provide as close as humanly possible to a ‘barrier’ against the weather.

NZ has a $47 billion ‘leaky building’ legacy to deal with[1], largely due to cladding systems and junctions being ineffective at resisting prevailing weather. If complete and effective wind tight WRB layers had been in place, then our buildings would have also been externally watertight. With a better understanding of the purpose of external membranes and control layers, we could have avoided this huge economic and emotional cost.

When Barriers go Bad

WRB systems that are designed to keep liquid water out can potentially trap water vapour in. By making structures more airtight on the outside in order to make them more waterproof, we risk creating systems that cannot dry out by means of incidental air leakage.

Internal Moisture

To keep walls dry we need to prevent water vapour being trapped behind our exterior WRB systems at the same time as preventing liquid water from entering from the outside. Water vapour will be present inside the wall at some stage in most climates, and it’s most likely to come from the interior of the building.

The easiest and fastest way that water vapour from indoors can reach the exterior WRB system is via gaps and cracks in the internal linings. Any air movement through these imperfections will transport water vapour along with the air. This movement generally occurs in the direction of warm to cold. That is, in winter when the interior of the building is (hopefully) warmer than the exterior, air will tend to flow from the inside of the building to the outside, taking water vapour with it.

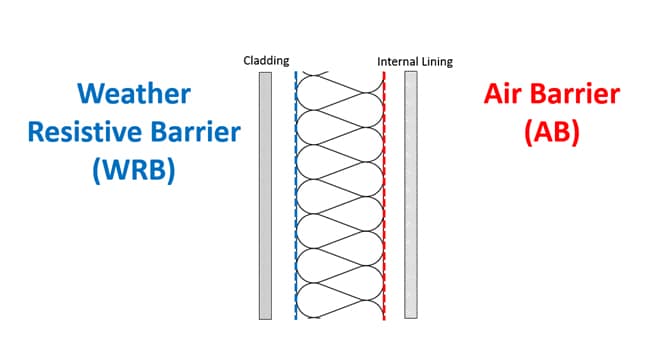

To prevent water vapour entering the building structure from the inside, we need to prevent the internal air leaking into that structure. We can do this by incorporating an internal air barrier.

Air Barrier

It is important to emphasise again that real barriers do not exist in real buildings. The objective is to get as close as possible to a perfect airtight seal on the inside to provide as close as humanly possible to an ‘air barrier’ to resist internal humidity from reaching the exterior cold layers.

The more airtight it is the better the humidity management works.

Where we Went Wrong

The obvious solution to prevent internal moisture in the form of water vapour from entering the structure is to add a near perfect barrier (‘retarder’ or ‘vapour check’) in behind the internal lining. We tried this for a short period in New Zealand with products such as foil-backed plasterboard. Foil (an effective vapour retarder) is still commonly used in Australia.

The application of vapour retarders follows the principle that assemblies should be as vapour resistive as possible. Such a principle holds true for part of the year, and in some parts of the World. For most of the climate regions of Australia and New Zealand however, the situation changes with the seasons or even daily and we need a vapour control layer that will respond accordingly.

Getting Smart

As barriers cannot be perfect in the real world, we should always aim for optimal resilience. In the event that water vapour transported by air does get through any imperfections, we want to ensure that the drying potential of our construction is maintained and always maximised.

We ensure drying potential and thus resilience by following the golden rule: Assemblies should always be as vapour permeable as possible and as vapour resistive as necessary.

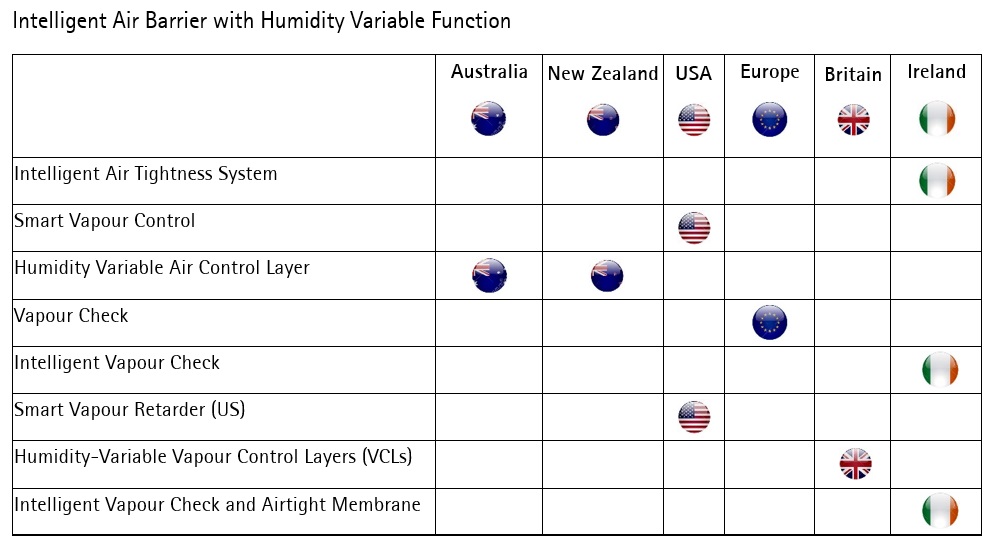

In winter we need our internal air barrier to be a vapour barrier (or very close to it) to prevent water vapour migration from the warm interior to the cold exterior surfaces. But in summer we want the internal air barrier to be vapour permeable in case water vapour comes back inwards from the warmer exterior (a process known as ‘back diffusion’). This ability to handle seasonal (or even daily) changes is referred to as ‘smart vapour control’, where ‘smart’ describes the ability to adjust the vapour permeance in accordance with the surrounding relative humidity.

Putting it all Together

On the exterior, we must have protection from two forms of moisture. Firstly we need to reduce liquid water ingress from wind leaks. Secondly, we need to control water vapour diffusion through our WRB. The system should dry out while also preventing excessive back-diffusion.

On the inside, we must protect the structure from internal water vapour. (Hopefully, liquid water is not an issue on this surface. If it is, the building has much more significant issues!) The internal layer must act as an air control layer to stop moisture laden air migrating into the system from inside, and as a vapour control layer to prevent water vapour migrating into and out of the thermal control layer (insulation) depending on the conditions.

Our internal air barrier must be connected with durable seals such as TESCON VANA to deliver an Intelligent Air tightness System (Ireland), Smart Vapour Control System (UK), Humidity Variable Air Control System (NZ), or a Smart Vapour Retarder (US).

Making Sense of the Jargon Soup

A barrier by any other name is still a barrier – except when it’s not. Our ability to understand the science of good building practices depends, in part, on our ability to communicate the science. The difference between a ‘retarder’ and a ‘barrier’ may seem like semantics and as inconsequential as muddling your dwangs from your nogs.

But when it comes to understanding the flow of liquid water, air, heat and water vapour through our building elements, accurate nomenclature matters. Let’s start our important Southern Hemisphere building science journey on the right foot by adopting sensible definitions that are helpful to our understanding of what matters for healthy, comfortable and resilient buildings.

For more in depth analysis of construction systems during summer and winter conditions in New Zealand, contact Pro Clima for your copy of “A New Zealand Based Study on Airtightness and Moisture Management”.

[1] Rottenomics; https://leaky-buildings.peterdyer.nz/

Authors

Recent articles

- The Perfect Pod July 24, 2024

- Above Sheathing Ventilation – Part 3: Fighting the Sun December 13, 2021

- Above Sheathing Ventilation – Part 2: The Blue Planet October 26, 2021

- Thermoplastic Elastomer Ether Esters: What are they, how do they work? September 19, 2021

- Above Sheathing Ventilation – Part 1: Rise of the Cavity May 4, 2021