It’s All Just a Façade

My mother always told me that looks aren’t everything—it’s what’s inside that truly matters. When it comes to façade design, I believe the same principle applies: what’s inside counts most, and the exterior can always be decorated to suit any vision.

The water control, air control, vapour control and thermal control layers are the most critical aspects of a low-risk façade design, all hidden on the inside.

As anticipated, the 2022 building code changes have transformed the construction landscape, making it unacceptable to erect buildings that foster mould growth within their fabric. In this new environment, a quantifiable design threshold has been established, grounded in theoretical calculations predicting the likelihood of mould growth within an assembly. These calculations are based on the Finnish Research Institute’s mould growth models, which allows assessment of risk according to the materials chosen for façade design using WUFI software.

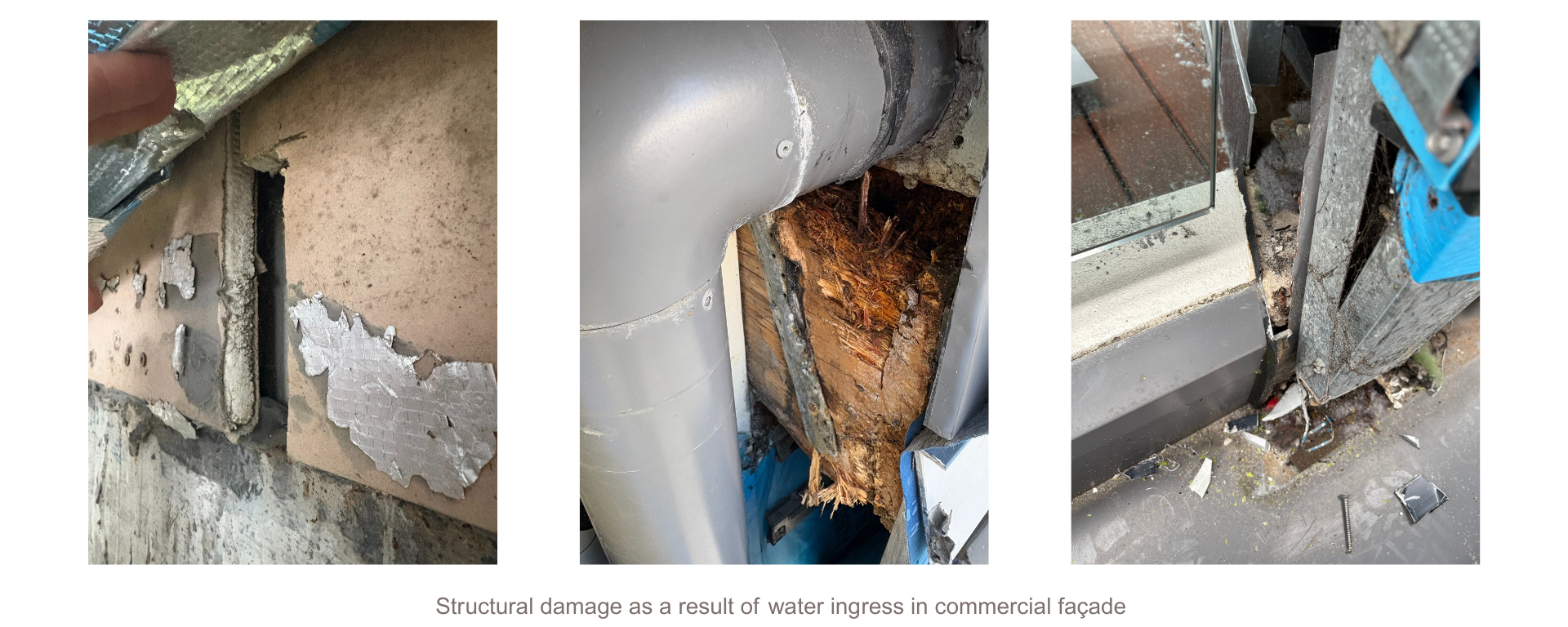

The health and amenity section of the building code now stipulates a maximum mould index of 3—or, as referenced in the Finnish research, no more than 10% visible mould coverage on any surface. Mould requires moisture, which can result from either water ingress or condensation due to poor material selection.

On May 2nd, 2025, I received an email stating:

“I am a construction lawyer at Clayton Utz assisting with a stalled major project affected by water ingress. As part of the causal analysis, we are investigating the façade design and construction, and the possible condensation buildup therein. We understand that within your company, Jesse Clarke has experience performing WUFI condensation modelling.”

In essence, there’s a legal dispute involving moisture and mould within a building envelope. The source of the moisture is unclear, and the investigation is ongoing. Regardless, both the weatherproofing and condensation management sections of the building code are designed to prevent unhealthy conditions, illness, or loss of amenity due to moisture.

Notably, the condensation management section specifies mould thresholds, providing lawyers with a powerful tool. The threshold of 3 effectively gives this tool a trigger. While the weatherproofing section does not explicitly mention mould, the presence of mould in a building inevitably prompts a causal analysis: Did it leak, or did it result from condensation?

Weatherproofing and condensation management are inherently linked. Failures in weatherproofing allow significantly more moisture into a construction system and remain the primary concern when designing and building dry, healthy structures. Condensation, meanwhile, can be a side effect of high-quality, well-sealed weatherproofing systems. The most vapour-permeable systems often rely on flexible membranes, which may compromise long-term durability as wind stresses the material. Rigid board systems, while robust, risk fracturing and water ingress under pressure. The most resilient weatherproofing systems use rigid sheathing to support adhesive membranes, but this can restrict vapour diffusion and drying. As with many design challenges, façade design involves balancing robustness against drying capacity—essentially, weighing the risk of water ingress against the risk of mould growth.

Although the legal landscape may feel like a game of Russian roulette, success is always achievable through thoughtful design, meticulous detailing, skilled workmanship, and careful product selection.

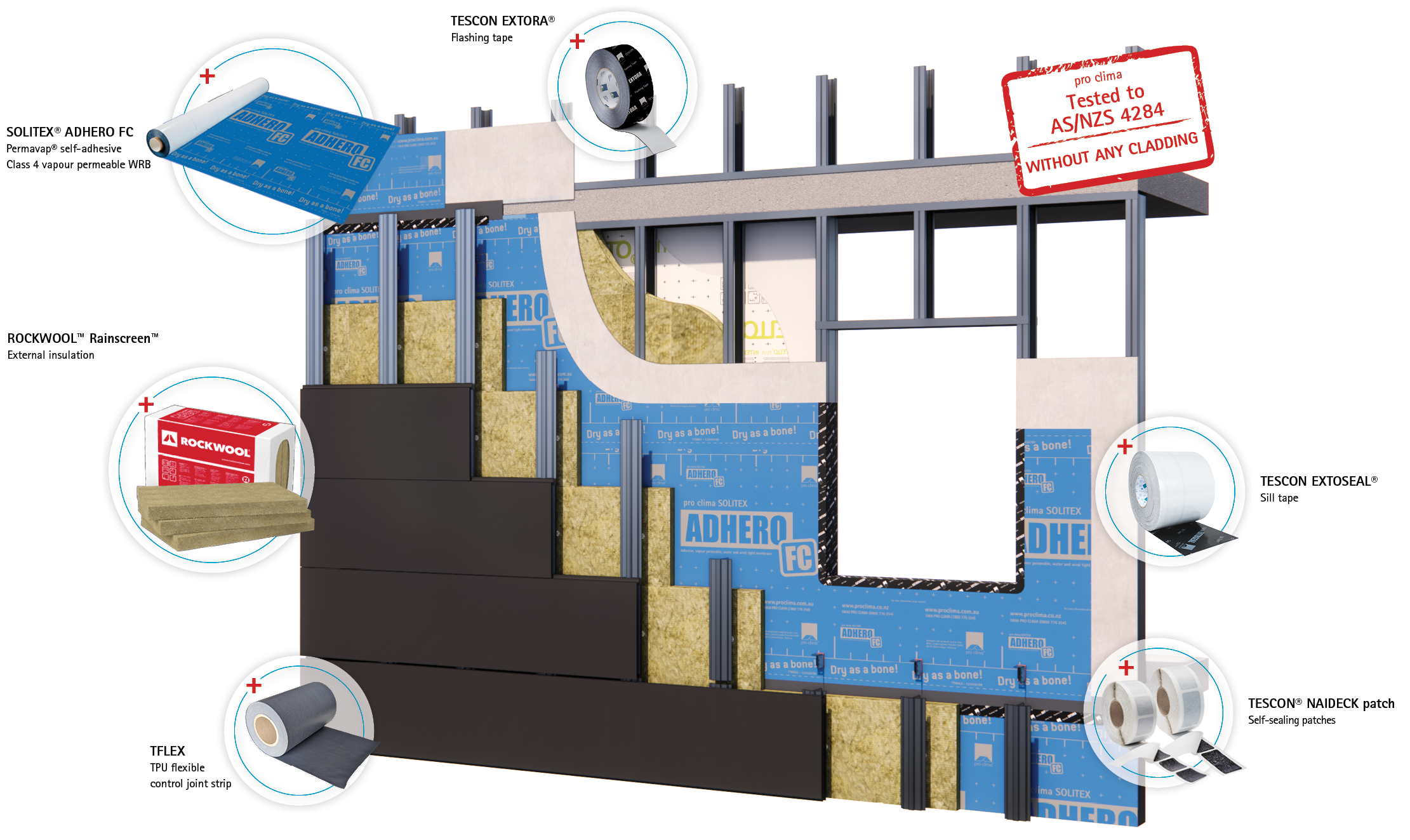

Fully weather tested systems provide the foundations for design and construction detailing. The industry has progressed rapidly since the adoption of AS/NZS 4284 Testing of Building Façade in 2016 and the solutions keep evolving.

pro clima’s new FORTX™ system is the state-of-the-art weathertight façade system tested without cladding to NCC verification method for weathertightness, enabling compliant designs with any cladding and racking system. Providing full architectural freedom and peace of mind for designers, engineers and the building occupants.

FORTX™ MELIOR takes the system to the ultimate level with fully non-combustible, hydrophobic layer of ROCKWOOL Rainscreen® to improve thermal performance, and manage condensation.

Join us as we unveil pro clima’s new façade solution at our exclusive launch event – Freedom to Design. Confidence to Build.

Event Details:

📍 Pro Clima Sydney Hub

📅 10 March 2026

🏬 15–21 Doody St, Alexandria

🗣️ Featuring a keynote with Hartwig Keunzel – developer of WUFI® and leading building physics expert from the Fraunhofer Institute.

Attend the FORTX™ Launch Event

You can also hear more about these new systems and meet the pro clima Australia and New Zealand team at:

Zak World of Façades

– 19 February 2026 – Brisbane Convention and Exhibition Centre

– 26 February 2026 – Crown Conference Hall, Melbourne

Building Science Summit New Zealand

– 2 March 2026 – Christchurch

– 4 March 2026 – Wellington

– 6 March 2026 – Auckland

Authors

Recent articles

- It’s All Just a Façade January 28, 2026

- German School Buildings Top The Class November 21, 2024

- The Perfect Pod July 24, 2024

- Above Sheathing Ventilation – Part 0: Flat Roofs September 12, 2023

- Above Sheathing Ventilation – Part 3: Fighting the Sun December 13, 2021